In 2022, the idea of a 3d Print On Demand venture sparked my imagination, brimming with possibilities for a new side hustle. Now, with a year of hands-on experience, it’s time for an update. Let’s delve into my journey, exploring what I’ve accomplished and the realities I’ve encountered in the world of 3D print on demand.

My specific aim? To carve a niche in 3D-printed jewelry. Since embarking on this path in 2022, I’ve dedicated myself to mastering the art of crafting 3D models optimized for both 3D printing and metal casting. The learning curve was steep, demanding a nuanced understanding of design principles to ensure the final product’s integrity and aesthetic appeal post-printing and casting. The goal is to create pieces that not only survive the production process but also faithfully reflect the original design intent.

The Startup Costs of a 3D Print on Demand Venture

One aspect that continues to impress me is the accessibility of 3D printing technology. My resin 3D printer, acquired in 2021, was surprisingly affordable, costing just over $300. This relatively low entry point democratizes the initial investment required to start experimenting with 3D print on demand.

However, while the printer itself is budget-friendly, the расходники, particularly resin, present a different financial picture. Importing specialized resin to Switzerland significantly increased costs, approximately $80 per batch. Despite this higher material cost, the actual printing process remains economical. Jewelry pieces require minimal resin, translating to just cents per piece in material cost. This efficiency allows for cost-effective prototyping and production runs.

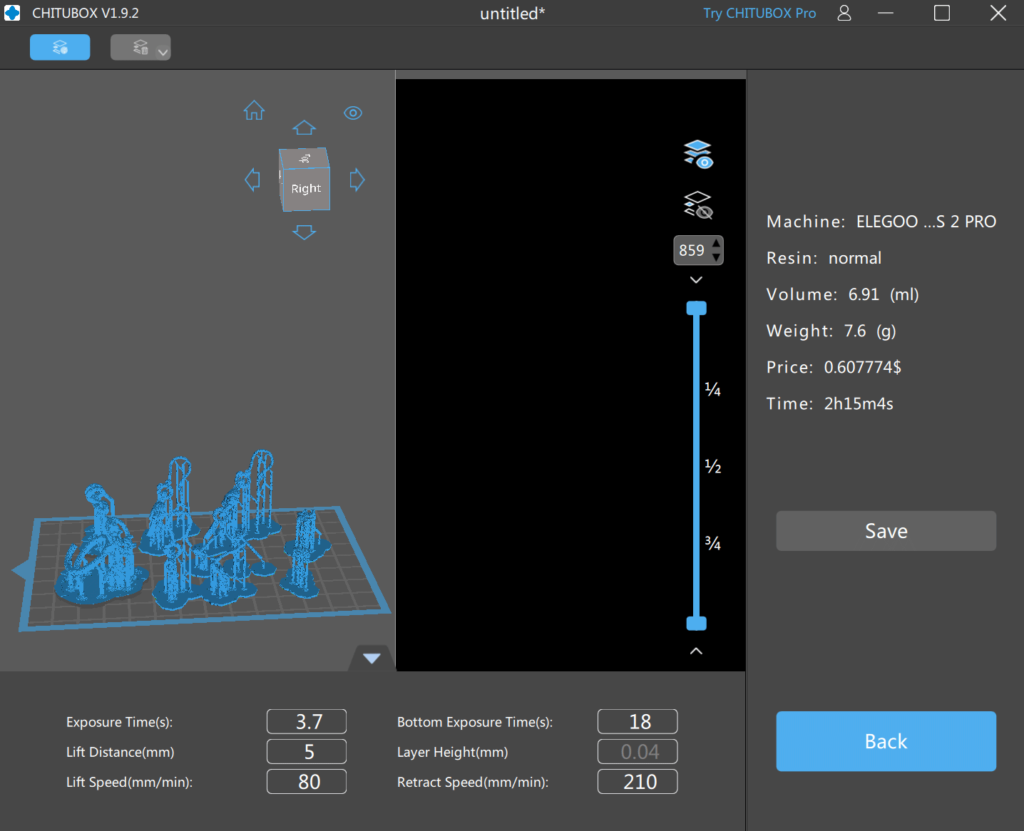

The image below illustrates a selection of jewelry prototypes alongside my 3D printing software interface. The software estimates the cost to print this entire batch at a mere $0.60, highlighting the low material expenditure per item.

.6.](https://amazingprint.net/wp-content/uploads/2025/03/chitubox-printing-price-1024x831.jpg) A screenshot of Chitubox software displaying a selection of jewelry 3D models ready for printing, with a calculated printing cost of .6.

A screenshot of Chitubox software displaying a selection of jewelry 3D models ready for printing, with a calculated printing cost of .6.

Resin printing, known for its precision, also comes with its share of mess. A washing station becomes an almost indispensable accessory for maintaining a clean and efficient workflow. This addition set me back another $141, an essential investment for anyone serious about resin 3D printing.

Cleaning resin prints effectively necessitates a potent solvent like Isopropyl alcohol. Filling the washing station to a sufficient level requires about three bottles, each costing around $12, totaling approximately $36 for a single fill. This recurring cost is a factor to consider in the operational expenses of 3D print on demand.

Below is a snapshot of my initial order, encompassing the 3D printer, washing station, and Isopropyl alcohol. Note that the resin itself was sourced separately.

A screenshot of a 3D printing starter kit order from 3djake.com, including an Elegoo Mars 2 Pro 3D Printer, Elegoo Mercury Plus washing station, and Isopropyl alcohol, totaling approximately 7.

A screenshot of a 3D printing starter kit order from 3djake.com, including an Elegoo Mars 2 Pro 3D Printer, Elegoo Mercury Plus washing station, and Isopropyl alcohol, totaling approximately 7.

Given the inherent toxicity of resin, personal protective equipment is non-negotiable. A high-quality respirator mask, costing $100, is a crucial investment for health and safety. With this mask, I can effectively eliminate any resin odor, ensuring a safer working environment.

A person wearing a professional respirator mask during 3D printing work, emphasizing safety precautions.

A person wearing a professional respirator mask during 3D printing work, emphasizing safety precautions.

Additional minor expenses included nitrile gloves and safety glasses, rounding out the essential safety gear.

In summary, the initial outlay for launching my 3D printing side project amounted to roughly $700.

At this juncture, a pertinent question arises: if the business model is “print on demand,” relying on external companies for printing and fulfillment, why the necessity for a personal 3D printer? The subsequent section will address this key aspect.

The Inherent Costs of Product Development in 3D Print on Demand

Prototyping is paramount in the realm of 3D print on demand, especially when aiming for quality and customer satisfaction. Test printing each jewelry design is crucial to preemptively identify and rectify any flaws that might compromise the final product’s aesthetics or durability in the hands of a customer.

A close-up of a 3D printed geometric jewelry piece in resin, showcasing intricate details and design.

A close-up of a 3D printed geometric jewelry piece in resin, showcasing intricate details and design.

My process involves initial test prints in resin to meticulously evaluate the design’s translation into a physical object. This stage allows me to scrutinize details at real-life scale and confirm the overall design coherence matches my vision.

Once a resin prototype meets my standards, I proceed to order a metal cast “test print” through Shapeways, a 3D printing service. Depending on my confidence level in the design’s robustness, I opt for casting in either cost-effective bronze or brass, or the more premium silver for designs I’m more certain about.

The following image provides a pricing breakdown for a pendant design, illustrating the material options available through Shapeways and their respective costs. Notice the accessible price points for brass and bronze, facilitating experimentation without significant financial risk.

A Shapeways.com pricing screenshot for a 3D pendant model, displaying material options and costs for 3D printing, highlighting affordable choices like brass and bronze.

A Shapeways.com pricing screenshot for a 3D pendant model, displaying material options and costs for 3D printing, highlighting affordable choices like brass and bronze.

For context, I chose black 420i Steel/Bronze(BJT) for a pendant commissioned by a friend seeking black steel geometric jewelry. The material offered a satisfying weight and an appealing matte black finish.

A photograph of a black steel geometric pendant, created via 3D printing and processing by Shapeways, displayed against a clean white backdrop.

A photograph of a black steel geometric pendant, created via 3D printing and processing by Shapeways, displayed against a clean white backdrop.

The Price of Experimentation in 3D Printing Materials

The technical parameters for 3D printing and casting across bronze, brass, silver, and gold are largely consistent. This similarity allows for material experimentation without drastically altering the design or printing process. When venturing into uncharted design territory or pushing the boundaries beyond my 3D printing service’s recommended specifications, I consistently choose a budget-friendly metal for initial trials.

Regarding minimum specifications: Services like Shapeways provide guidelines to ensure print reliability. However, these guidelines are not immutable. I discovered that for jewelry, particularly pieces with interlocking components, adhering strictly to minimum spacing requirements can result in bulkier, less refined designs. I’ve since experimented with progressively tighter tolerances to achieve a more delicate, handcrafted aesthetic.

As long as the structural integrity of the print and cast remains uncompromised, Shapeways typically processes orders even if dimensions fall slightly outside their prescribed specifications. This flexibility is invaluable for pushing design boundaries.

Upon receiving a metal-cast jewelry piece, a thorough inspection follows to determine its market viability and identify any areas for refinement. Pieces that meet my quality standards proceed to the next stage: professional photography and listing in my Shapeways shop.

Product photography, especially for jewelry, is a specialized skill I’m actively developing. Capturing the luster and detail of small, reflective objects presents unique challenges.

Through this iterative process, I’ve successfully launched 5 product listings since 2022.

Admittedly, five products in two years may seem modest. However, this figure belies the extensive experimentation and learning invested in reaching this milestone. Numerous other designs are finalized and awaiting the photography and listing phases.

To date, test prints from 2022 onwards have accumulated to approximately $1000 in expenses.

This sum encompasses multiple iterations of several designs as part of my ongoing learning and refinement process.

However, simply listing products is insufficient for sales. The subsequent critical step is marketing.

Marketing Strategies for 3D Print on Demand Jewelry

Marketing presents the most formidable hurdle. While not necessarily capital-intensive, it demands significant dedication and time investment.

The jewelry market is intensely competitive, and gaining visibility for your products is exceptionally challenging. The Shapeways marketplace, where my shop is hosted, suffers from negligible organic traffic, as corroborated by data from ahrefs.

An ahrefs screenshot showing minimal monthly traffic (1.5k) to the Shapeways marketplace, indicating low organic visibility.

An ahrefs screenshot showing minimal monthly traffic (1.5k) to the Shapeways marketplace, indicating low organic visibility.

Ahrefs data indicates a meager 1,500 monthly visits to the shapeways.com/marketplace subdomain in the US, constituting 74% of its total traffic. Extrapolating this data suggests a total monthly traffic volume of around 2,000 visits globally.

Compounding the low traffic volume is the likelihood that marketplace browsers are not specifically jewelry shoppers, and certainly not within my target demographic.

Recognizing the Shapeways marketplace’s inherent traffic limitations from the outset, my strategy has consistently centered on social media promotion. Let’s examine the effectiveness of this approach.

Social Media Promotion Efforts

My initial social media strategy prioritized platforms with strong visual content potential: YouTube Shorts, TikTok, Instagram, and Pinterest. I established accounts on each platform and commenced content posting.

My content mix included:

- Finished jewelry product videos and photos

- Time-lapse videos of jewelry 3D modeling

- Previews of 3D models within Blender 3D software

- Videos showcasing resin test prints, support removal, and wear tests

- Unboxing videos of metal cast test prints

- Humorous 3D modeling perspectives

- Behind-the-scenes glimpses of photo sessions

I leaned heavily into short-form video content, given its proven engagement rates, supplemented by longer-form videos and static photos on platforms supporting those formats.

Instagram Performance

Instagram yielded mixed results. My initial five reels each garnered nearly 200 views, possibly due to an initial platform algorithm boost for new accounts. Subsequently, views plummeted, from 29 to 4 to 0. I paused posting after this decline.

Across nine reels and one photo, I accumulated a modest four followers and zero likes. View data beyond six months is inaccessible via Instagram analytics, but despite the underwhelming initial performance, I recognize Instagram’s potential for niche community engagement and remain open to future strategies.

TikTok Engagement

TikTok received the most focused attention due to its comparatively stronger initial engagement. Videos averaged around 200 views and 10 likes, with peak views reaching 1,900.

After 25 videos, my TikTok account stands at 700 likes and 29 followers.

While not explosive growth, it surpassed the engagement levels on other platforms. TikTok was also the only platform generating comments, albeit sparingly.

High-performing video types included:

- A concise (7.6s) video showcasing a peculiar 3D modeling anomaly with a voiceover explanation, capitalizing on curiosity and humor, achieving 1,971 views.

- Time-lapse jewelry 3D modeling videos in Blender, ranging from one to two minutes. The shorter video continues to attract views organically even after account inactivity.

Beyond content optimization, I incorporated trending TikTok audio tracks cleared for commercial use. Leveraging non-commercial trending sounds might amplify reach further, but raises legal considerations.

YouTube Shorts Performance

YouTube Shorts offered moderate encouragement, with videos achieving respectable views given the account’s nascent, follower-free status.

A screenshot of YouTube Analytics displaying views on Shorts, indicating varied performance with some videos exceeding 5,000 views.

A screenshot of YouTube Analytics displaying views on Shorts, indicating varied performance with some videos exceeding 5,000 views.

My YouTube content comprised:

- One long-form video (2.5 minutes): a 3D modeling time-lapse.

- 13 Shorts: primarily repurposed, top-performing TikTok content.

Key YouTube Shorts metrics:

- Most viewed video: 5,043 views

- Average video views: 900

However, viewer demographics were less promising. India accounted for 25% of views. My jewelry’s price point likely exceeds the affordability threshold for most Indian viewers, or views may originate from jewelry suppliers.

A screenshot of YouTube Analytics showing viewer geography, highlighting India as a significant view source (25%), raising questions about target audience relevance.

A screenshot of YouTube Analytics showing viewer geography, highlighting India as a significant view source (25%), raising questions about target audience relevance.

The practical business value of moderately successful YouTube Shorts, given the demographic skew, remains uncertain at this stage.

Pinterest Performance

Pinterest’s performance fell short of expectations, particularly considering my focus on video-centric idea pins.

My Pinterest activity included 12 pins: 9 idea pins and 3 static image pins.

Peak impressions reached 177 on an idea pin, with the top-performing pin generating 9 clicks. One idea pin even received a “heart.”

A screenshot of a Pinterest pin showing a heart reaction, indicating minimal but positive user engagement.

A screenshot of a Pinterest pin showing a heart reaction, indicating minimal but positive user engagement.

Pinterest holds untapped potential. Consistent, dedicated effort is needed. Past experience building Pinterest accounts to over 200k monthly impressions suggests achievable growth with focused strategy.

Social Media Marketing: Overall Assessment

My initial social media marketing outcomes were underwhelming. I anticipated easier reach given the volume of content produced. However, social media algorithms favor daily consistency, which I lacked. Inconsistent posting frequency likely contributed to suboptimal performance. Re-implementing scheduling tools to ensure consistent posting is a priority.

3D Print On Demand Side Hustle: Results to Date

After considerable effort, the ultimate question: Have I made any sales?

No.

Am I $1700 out of pocket?

Yes.

Was it enjoyable?

Absolutely. Immensely so. The process itself has been rewarding, irrespective of immediate financial returns.

Future Directions

I’m contemplating opening an Etsy shop and exploring dropshipping for my jewelry line. However, concerns linger regarding customer service demands without direct product oversight and potentially protracted 3-4 week shipping times, which may not align with Etsy customer expectations.

On a positive note, I possess a substantial backlog of unreleased content. Untapped potential remains across all social media platforms.

I’m not ready to abandon this 3D print on demand venture. Further exploration and refinement are warranted.